Reasons to buy the best platinum melting furnace

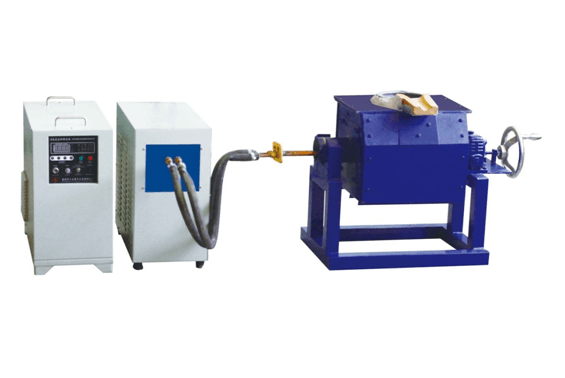

Production of platinum has come a long way from traditional methods that used extreme heat, to the smooth and clean one-step procedure. Nevertheless, to increase the output and make the process easier, buying the best platinum melting furnace is essential. However, with the numerous equipment of the same functions in the market, choosing a high-quality platinum melting machine that meets your quality standards can be a challenge. Despite those challenges of getting the right melting machinery, let’s look at the benefits of buying a platinum melting furnace for business or personal use.

- They have powerful safety features

For many decades, platinum smelting has been considered as a risky activity. Since the platinum melting point is high, risks of burns and fire hazards are there. When buying a platinum melting machine, the threats are minimal because it has a powerful trigger cautioning system. Due to this, avoidance of potentially hazardous conditions is highlighted, thus letting you maximize production. This means that you will increase the income at minimal risks.

- The machine has zero combustion

When it comes to smelting precious metals such as platinum, a huge amount of carbon dioxide pollutions are the byproducts. In most cases, air pollution is attributed to outdated combustion of oxygen with fuels. Buying a modern platinum melting kit minimizes environmental pollution via the prevention of using carbon effluents as a source of heat.

- Offers a lower power consumption

Unlike traditional techniques that used coal as a heat source, metal melting machines use electricity as the main source of power. The utilization of electricity allows the smelting of precious metals at high efficiency. This limits the guesswork on if the entire metal has dissolved or not. Furthermore, the use of an induction machine lessens the time required since the process is completed within minutes.

- Guarantees reduced wastage of precious metal

With a platinum melting furnace, smelting of the platinum is completed practically and cleanly since there is no open fire source and spillovers. Efficient metal smelting means that the loss of precious metals is minimized. Idyllically, with this metal melting machine, the utilization of cubicles is incorporated into the construction of the furnace system. So, the self-contained construction streamlines the recovery of precious metals. This reduces the waste of platinum during the production process.

- It is easy to maintain a platinum melting furnace

The utilization of melting machines for platinum production provides a simple and efficient maintenance option. Since these furnace types come with a removable cubicle, you will have easy access, and for this reason, separation and cleaning are completed within a few minutes. Additionally, it has an in-built water feature for pump connections that plays a role in preventing overheating of the main system. Since the machine can be separated in various elements, replacing any part in case of done can be done fast without replacing the entire melting machine.

Final word

Investing in the best platinum melting furnace guarantees you high-quality production of the metal. Additionally, you won’t need the constant help of technicians since operations of the platinum melting machine are manageable and sleek. With these benefits, you can’t afford to buy an induction machine for business or home use.