How To Reduce The Cost Of Injection Moulding

Contrary to popular belief, the injection moulding process dates as far as the late 1800s. Back then, the method was used in the production of items like combs and buttons. The products that were produced in the process were used by primary consumers, in the health care industry and the aerospace industry as well. The most significant history of injection moulding is when it was applied in the manufacture of billiard balls by John Wesley Hyatt in 1868. By the mid-1940s, the method made way into the plastics manufacturing industry.

This is also the time when the screw injection moulding device was invented and used for the first time. Since then, plastic injection molding company has become a widespread phenomenon. The main reason for the popularity of the method is that it is cost-efficient. In this article, we look at the factors that influence the cost of injection moulding.

Factors influencing the cost of injection moulding

Below are the main factors that affect the financial aspects of injection moulding;

- Material used

The material used in injection moulding is referred to as the resin. The type of resin used in the process significantly influences the value and quality of the final product. The type of resin also influences the cost of the process. For instance, different materials of different values feature varying costs. The quantity of material used also affects the overall cost of the process. The resin also tends to cost more if it is not readily available as the rarer it is, the more costly. Other factors affecting the cost of the material include the color, grade, compounding, and additives used. Finally, the temperature required to transform the resin into molten form and to cool it back down affects the overall cost of the injection moulding process.

- Design and size

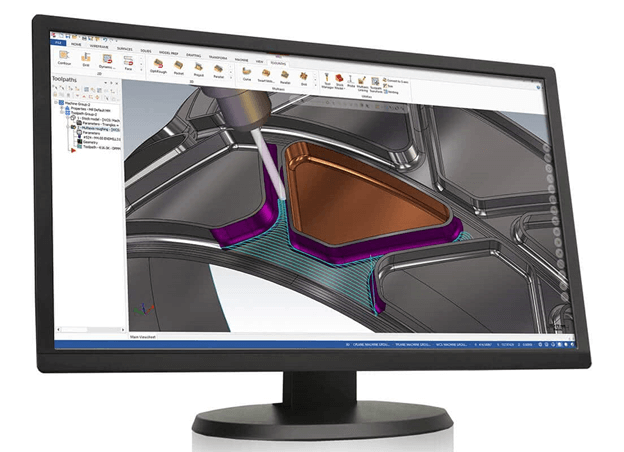

The design of the parts intended for manufacturing is also a significant determinant of the cost of production. Significantly intricate parts require intricate mould design. Designing the mould is the costliest element of injection molding. Therefore, simplifying the plan would go a long way in reducing the cost of the process.

On the other hand, the size of the part affects such aspects as the time used and the number of materials used. This means that more significant parts would require larger moulds and larger quantities of materials. The materials used in the making of the larger moulds also affect the cost. It is, therefore, more cost-convenient to produce a smaller and thinner part in injection moulding.

- Time

The amount of time that it takes to complete a single round of production is known as the cycle time. Therefore, if it takes ten seconds to end production of an only part, it means that in an hour, you will produce three hundred and sixty parts. The lesser the cycle time, the more cost-efficient the process is.

Take Away

Another factor that affects the cost of injection moulding is the quantity of production. Typically, the higher the number means that the price would also be high. However, the contrary is true in injection moulding. This means that it is cheaper to manufacture more substantial quantities.