Points to Note When Picking Your PCB Manufacturer

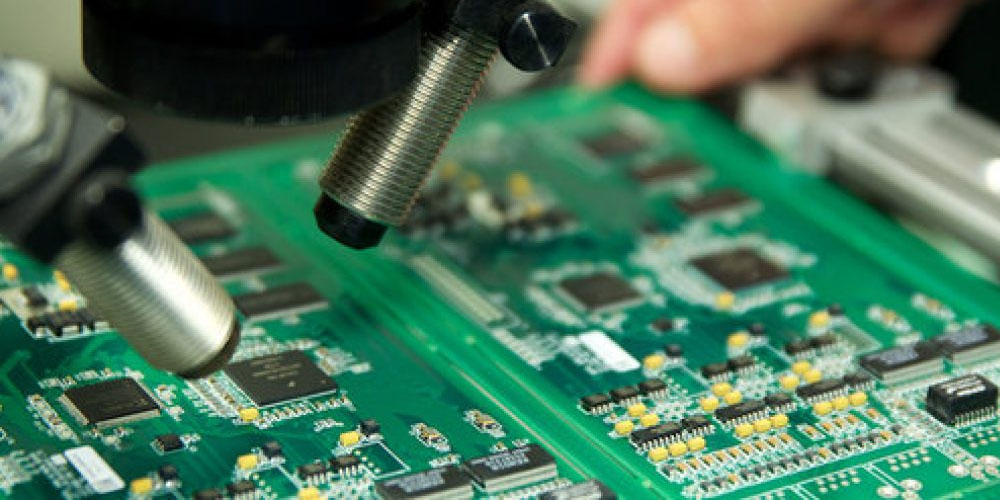

PCBs or printed circuit boards act as a base for electronic components to provide mechanical support. PCB manufacturing involves a series of steps that apply different technologies; hence the boards vary depending on the application. Several PCB manufacturing companies have developed to offer services. This process requires high expertise and machining equipment to produce the best product; therefore, choosing the proper manufacturer is vital. In this post, we highlight the PCB manufacturer selection tips.

Tips for Choosing the Ideal PCB Manufacturer

The following are factors to consider when selecting the best PCB manufacturer.

1. Manufacturer’s capabilities

When selecting a producer for your goods, the first step is to ensure they can make the goods for you. Different suppliers have varying capabilities. For example, some develop all kinds of PCBs while others may manufacture one or two types only. The manufacturer should understand and be familiar with the service you want and have the necessary equipment to complete the job. Having machines for several manufacturing steps is vital to reduce costs and times taken looking for another company to carry out the processes. In addition, select a manufacturing plant that applies new technologies to produce high-quality and more efficient PCBs. Ensure testing is done to prove viability and proper functionality.

2. The PCB costs

Prices differ between manufacturers based on reasons like the cost of production, laborers, materials, and many others. Typically, having your PCBs produced abroad is cheaper than locally; however, the total costs can increase due to shipping, tariffs, tracking, and communication. Also, they may take longer to get to you. Some local manufacturers can offer you discounts hence lowering the costs, the waiting time is less, and you can check in with the manufacturer anytime. Always consult both parties before settling for one.

3. Quality of the product

The quality of any product is influenced mainly by the manufacturer’s certification. If the supplier is certified, there is a particular production level he or she cannot go below. Ensure the company has a quality management system that follows basic work rules, policies, quality levels, and preventive measures. A competence certificate should back up preventive and safety measures. This is to show that the processes and environment are safe for use. Poor quality PCBs have a poor lifespan and tend to suffer damages quickly.

4. Duration of delivery

Each supplier gives an estimated lead time for products. Select one with a good record of sticking to the time and delivering goods safely. Check the company’s rating and reviews regarding services offered to other customers to know its performance. Good feedback gives you the confidence to entrust the manufacturer with your goods and look for another supplier if the responses are negative.

Final word

Your choice of manufacturer highly influences your product’s performance. Go for reasonably priced goods but don’t compromise on quality. Ensure the production company meets all your requirements and can develop high-quality objects. Research extensively and choose the best manufacturer either locally or abroad.