5 Proven Ways to Lower Injection Molding Cost

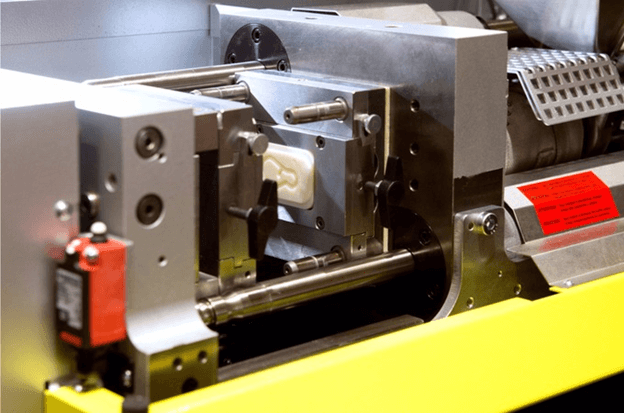

Bringing a product to the market is always a challenging thing. Creating something from an idea is never without hiccups and drawbacks. Injection molding has been and still is one of the most popular production methods for bringing physical products to life.

Injection molding is a process that has been used in the production of various products, decades before we get to know about 3D printing. But even with the rise of 3D printing, plastic injection molding is still growing strong. It still is the favorite manufacturing method for many manufacturers from all parts of the world as it holds many advantages over 3D printing.

The main battlefield between 3D printing and plastic injection molding is production cost. In 3D printing, the cost is pretty much sealed, and there isn’t much room for maneuvering. On the other hand, there are ways to lower injection molding costs. Here are five ways to make the most of your manufacturing dollars.

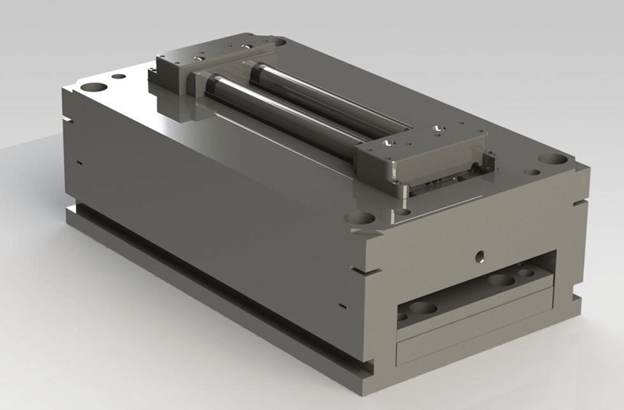

1. Get an Estimate for the Injection Mold

The injection mold will take a big chunk of your budget. Getting it made for the lowest possible price is essential if you want to keep the manufacturing cost as low as possible. To that end, you may want to get as many quotes from mold makers as possible.

Additionally, you can try and figure out the price of injection mold on your own. The price of the injection mold is determined by several factors that are well-known within the molding industry.

2. Unnecessary Features

Molded part numbers, textured surfaces, molded company logos, all that looks splendid. However, they are non-critical features that will only increase the manufacturing cost. Molded numbers are a must-have if you are making parts for the army or the aerospace. But for everyone else, not so much. So, if you want to keep the manufacturing cost low, try to avoid unnecessary features such as those.

3. Cosmetics

Great looking parts are visually pleasing, but that extra touch to make them look like that often comes at a price. Very often, it comes with extra cosmetics, high mold polish, EDM, or even bead blasting. Any finish higher than PM-FO means that there is some hand-work included. The recommendation here is to polish what it needs to be polished as opposed to the full side of the mold.

4. Self-Mating Parts

Let’s say you need to make two interlocking halves that need to snap together. The smart play here is to make one instead of two. A simple redesign can make the snaps in a way so that the halves will be able to fit together from both directions. That means creating something known as a “universal” part. The fact that you will need only one mold will save you a ton of money upfront.

5. DFM Analysis

Last but not least, a DFM analysis can identify impossible geometries, un-machinable features, and other potential design flaws. You can also detect things that need to be fixed or removed before getting the final approval. So you either deal with them timely, or you better prepare for a set of new troubles along the road that will most likely hit your manufacturing budget.