Highlighting The Benefits Of Overmolding

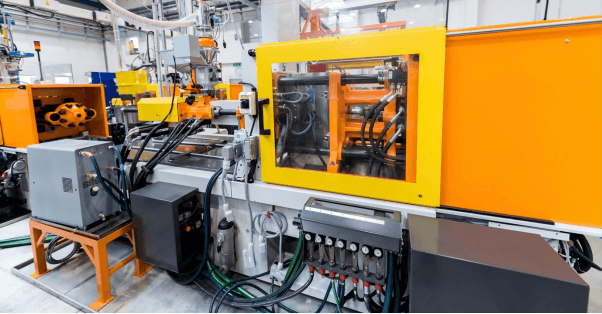

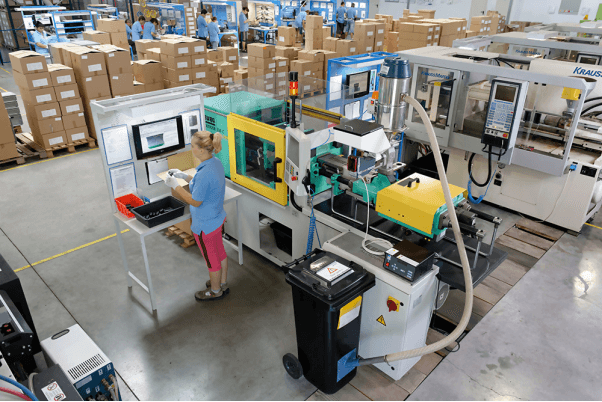

Overmolding is becoming the primary manufacturing process for those who are in the business of producing plastic. While it is overbearing as compared to other methods, it is also one of the most reliable processes of production since time immemorial. In this article, we shall look at some of the benefits of using an overmold in your production process. Here are the top pros of using the overmolding process in manufacturing plastic.

- Improved Variations Of Designs

While overmolding can have adverse effects on the design of your products, it is also one of the most reliable manufacturing processes, as we highlighted in the initial blog post. You will like the fact that it has a way of allowing you to create different yet unique products at a slightly shorter time as compared to other manufacturing processes that take longer. The design variations will also be somewhat marketable in the end. Of course, this is appended to the fact that the designs will highly have improved versions.

- Multiple Part Manufacturing Will Be Enhanced

If you are in the manufacturing sector, then you know how important it is for your clients to receive high-quality products manufactured using the best procedures in the world. Overmolding will make it possible for you to reproduce products in several parts. That way, you will be best positioned to cater to the varied needs of other users at the same time. With overmolding, you will be in a position to better define your prospects and target audience. That way, you can also assess their needs as well as requirements.

- Enhancing The Rating Of Your IP

If you decide to delve into overmolding for your production processes, you should work with a trained professional to achieve excellent results. When you work with an expert in charge of overmolding, you will be better positioned to achieve better results in terms of quality.

Other than that, you shall also be in a position to gain more in terms of the rating of your IP. This implies that you will gain access to a watertight seal in the significant electrical connections. Regardless of the regulations, you need to meet, your IP rating shall have been achieved. That way, you will protect your components from any form of material that can destroy them.

- Taking Advantage Of Compact Spaces

With overmolding as the primary manufacturing process, you can rest assured that you can easily take advantage of various compact spaces therein. If you are wondering how, then we shall highlight some of the key ways you can achieve this without struggling much! Your product team may be forced to design a device that can comfortably accommodate various spatial constraints. With overmolding in place, you will be in a position to create smaller yet strong products by assembling the right cables. You can also easily enable your team of designers to minimize your device’s size.

Take-Home

Overmolding is a viable process used in the creation of different plastic products. As indicated in this chapter, the process comes with several pros you will like in the long run. Not only will you be in a position to deliver high-quality products to your clients but also manufacture several products at once.