Top Advantages Of FDM Printing In The Tech World

The world is a center-stage of technology. Several companies have embraced the applications of 3D printing. For that reason, there are several printing techniques that you need to be familiar with. They are such as Stereolithography as well as Fused Deposition Modeling. In this article, you shall learn more about the pros of using a desktop FDM printer in your business. You shall also grasp the basis of FDP printing in the tech world.

- Enjoying The Low Cost

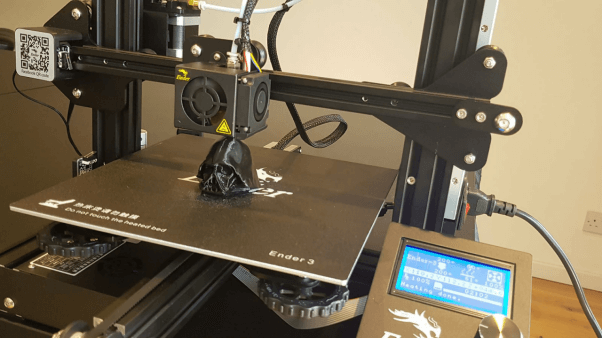

All too often, when manufacturing firms go for the FDM printing method, the reason appended to it is the low cost. Apart from that, the method is relatively user-friendly when compared to the rest. For many companies, it’s also one of the fastest ways to save money and spend it on a different project.

- Tie-Saving

Since the 3D printing industry is developing into one of the most competitive sectors in the consumer industry, several firms are still finding it challenging to select the right printing technique. That’s why it’s essential to comprehend the benefits of some of the prominent printing methods such as FDP. You’ll first like the fact that it is time-saving. This is because there’s post-processing is not required. By saving time, you’ll be in a position to cater to other impending projects.

- Ease In Handling

As the 3D printing world evolves, several companies are coming forward to embrace the technology and utilize it in elevating their businesses. There, therefore, no doubt that it shall soon become the primary way of creating parts as well as objects in the future. Not only does this method of production simplifies the manufacturing process, but it also makes it easy for producers to test and alter the final product.

- You’ll Enjoy The Fact That It’s Less Post Processing.

If you’re a revered business professional in the printing industry, then you should understand how time is money. The 3D printing business is growing at an alarming speed. Therefore, people are adapting to various printing methods. One such way is the FDM printing style, which needs less post-processing in the long run. This implies that you do not have to think about how to utilize expensive liquids like in other printing methods.

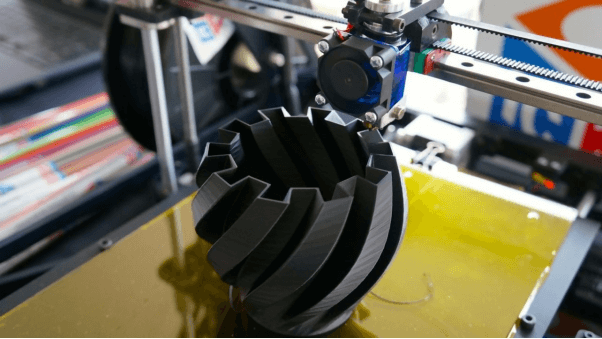

- You Can Use Different Materials In Printing

With conventional printing technology, you are restricted to using a few types of materials. But, with FDM printing technology, you can rest assured that you are free to use different printing materials and models, including HIPS, as well as PVA. This also implies that there is flexibility in choosing the materials to utilize in printing.

Take-Home

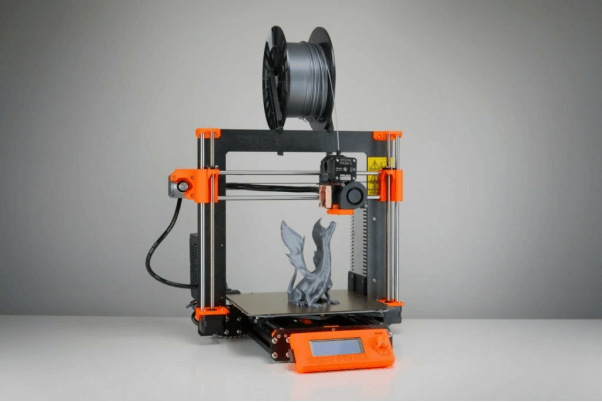

FDP printing is also known as fused deposition modeling, which is also identified as the freeform filament fabrication. It’s a process that utilizes a filament thermoplastic material. The filament is usually filled with a large coil that is heated via the extruder.